In Mold Decoration (IMD)

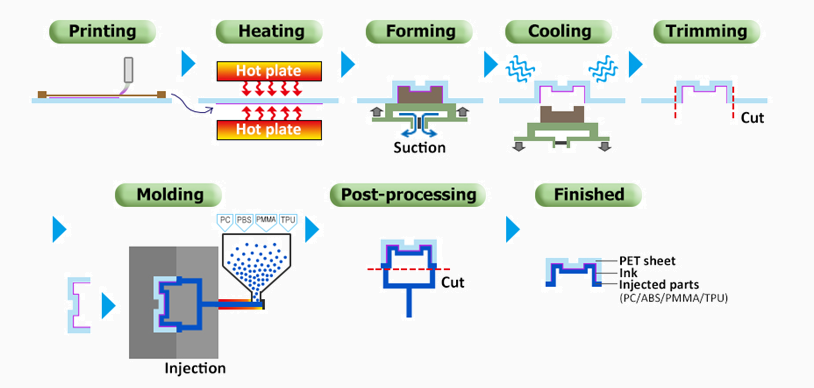

IMD PROCESS FLOW

“In Mold Decoration (IMD) is a versatile and cost effective method of decorating and manufacturing plastic parts,

best described as a method of In Mold Decoration (IMD). The flat film is firstly reverse decorated (normally screen printed), then optionally formed, trimmed and finally back injection molded.”

With IMD you can easily integrate components such as lens and body into a single unit using just one piece of our formable hard coated films.

THE ADVANTAGE OF IMD

| IMD | General Operation | |

| Pollutant | Less | Severe |

| Post-Production Duration | Shorten | Longer |

| 3D Impression | Excellent | N.A. ; Need Extra Parts Assembly |

| Wear Resistance | 2 H | < 2 H |

| Life | Durable | Easy Scrape Off |

| Quantity | Min. 3,000 | Min. 10,000 |