Design Guide

Material used : Silicone rubber

Function :Establish contact between the LCD & PCB .

All elastomeric inter-connectors are 'custom made' Zebra connectors offer a wide variety of application possibilities. Unlike other connectors, they do not entail soldering to make reliable connections. They require a minimum of installation hardware considerations, allowing for very small packaging structures to support low profile display and microelectronic interfacing.

When properly dimensioned, long-life performance can be assured and airtight connections without additional precautions can be realized.

PITCH OF INTER-CONNECTOR(P)

- More than three (3) conductive contacts per electrode of PCB/LCD.

- Distance from center-center of each conductor in a connector

- Alternate layers of insulation width (i) & conductor width (c) silicone material evenly spread over the entire length of inter-connector.

- e.g. Pitch (0.1 mm) = i (0.05 mm) + c (0.05 mm)

- Basically, 2 conductors per electrode are often adequate, but 3 conductors per electrode are always recommended to ensure reliable connections and to eliminate "intermittent contact"

- e.g. LCD pitch = 1.2 mm (with contact pad 0.6 mm)

Inter-connector pitch = 0.18 mm is recommended"

| Pitch | Application |

| 0.18 mm [standard] | Simple segment LCD |

| Fine pitch 0.1mm | Dot matrix LCD |

| Very fine pitch 0.05 mm | Graphics LCD |

| Finest pitch 0.03 mm | Graphics LCD in high requirement |

| The number of conductors per inch = pitch | |

| Conductors per inch | Pitch (mm) | Pitch (in inch) |

| 141 | 0.18 | 0.007" |

| 254 | 0.1 | 0.004" |

| 508 | 0.05 | 0.002" |

INTER-CONNECTOR - LENGTH(L)

- L > Length of LCD pads : ±0.2mm or above

- The overall length is recommended to be extended a min. of 0.5mm beyond the edge of the contact at each end of the connector.

INTER-CONNECTOR - WIDTH(W)

- W ≤ width of LCD ledge.

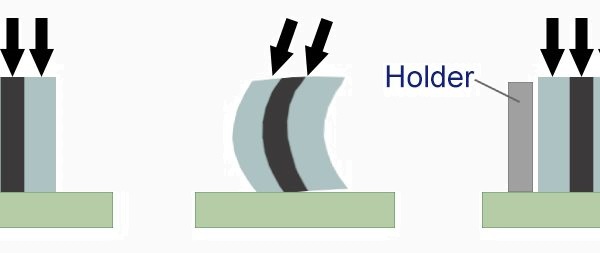

- Its design is critical in eliminating buckle when clamping force is applied to the connector.

- If the buckle is too severe, contact shall lost completely.

- If connector width is too thin, it may require holder to facilitate assembly, prevent accidental side contact & eliminate alignment problems.

INTER-CONNECTOR - UNCOMPRESSED HEIGHT(H)

- Connector height is determined by the separation distance between LCD & PCB, including tolerance variations.

- It is critical to calculate the correct compression ( deflection rate ) to be applied to the connector for reliable connections.

- Compression ( deflection rate ) to be applied to connectors varies with different types, dimensions of inter-connectors.

- Generally speaking, compression set for inter-connector is ~ 10 - 15%

- Guideline for reference :

- H < 6 mm, ~ 15% compression of connector's height

- 6 mm < H < 10 mm, ~ 13% compression of connector's height

- ≥10 mm, ~ 10% compression of connector's height

- X = n / 1 - p Formula to determine the uncompressed height of the connector

- x = uncompressed height

- n = compressed height (= separation distance between LCD & PCB)

- p = percent of desired compression

- Compression load should be spread evenly over the top surface of the inter-connectors.

- To avoid bending, we recommend to use holders especially for tall height inter-connector.

- Holder should give space for horizontal expansion of the inter-connector during compression.

CONDUCTIVE CORE WIDTH(YL)

- Conductive width is important in determining the cost, resistance and hardness of the connector.

- For connector width > 1.3 mm, the more conductive material a connector contains, the more expensive it is.

- Standard core width = 0.6 mm

APPLICATIONS

DESIGN GUIDE

- Pitch (P): More than three (3) conductive contacts per electrode of PCB/LCD

- Length (L) : + 2mm or above

- Uncompressed Height (H) : Distance between LCD & PCB +10-15% compression rate

- Width (W) : determined by the width of LCD ledge

SPECIFICATION